Top 5 features to look for in a heavy-duty trolley

In industries where heavy lifting is the norm, having

the right equipment is crucial for efficiency, safety, and productivity. Heavy-duty trolleys

in Perth are indispensable tools in such environments, offering the

means to transport heavy loads with ease. However, not all trolleys are created

equal, and selecting the appropriate one requires careful consideration of

various features. Whether you're in manufacturing, construction, warehousing,

or any other heavy-duty environment, here are the top five features to look for

when choosing heavy-duty

trolleys in Melbourne.

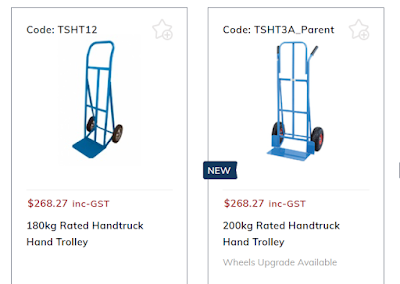

1. Load Capacity:

The primary consideration when selecting heavy-duty trolleys

in Sydney is its load capacity. Different applications require trolleys

capable of handling specific weight capacities. Before making a purchase,

assess the typical loads you'll be transporting and choose a trolley with a

capacity well above that to ensure safety and longevity. Opting for a trolley

with a higher load capacity than needed provides a margin of safety and

prevents overloading, which can lead to accidents and equipment damage.

2. Construction and Durability:

Heavy-duty trolleys in

Brisbane are subjected to rigorous use in demanding

environments, so durability is paramount. Look for trolleys constructed from

robust materials such as steel or aluminum, which offer exceptional strength

and resistance to wear and tear. Welded joints provide superior structural

integrity compared to bolted connections, enhancing the trolley's overall

durability. Additionally, consider factors such as corrosion resistance,

especially if the trolley will be used in wet or corrosive environments, to

ensure longevity and minimize maintenance requirements.

3. Maneuverability:

A heavy-duty trolley's maneuverability significantly

impacts its usability and efficiency. Look for features that facilitate smooth

movement, such as high-quality casters or wheels with bearings for easy

rolling, even under heavy loads. Swivel casters allow for greater

maneuverability, enabling the trolley to navigate tight spaces and corners with

ease. Additionally, consider features like ergonomic handles or steering

mechanisms that make it easier for operators to control the trolley, reducing

fatigue and improving overall productivity.

4. Safety Features:

Safety should always be a top priority when selecting

equipment for heavy-duty applications. Choose a trolley with built-in safety

features designed to prevent accidents and injuries. This includes features

such as locking mechanisms to secure the load during transport, ensuring it

remains stable and prevents shifting. Side rails or barriers can prevent items

from sliding off the trolley, reducing the risk of damage or injury.

Additionally, opt for trolleys with sturdy brakes that allow operators to

secure the trolley in place when loading, unloading, or stationary, preventing

unintended movement.

5. Versatility and

Customization Options:

The ability to adapt the trolley to various tasks and

environments adds value and versatility. Look for trolleys that offer

customization options or compatibility with accessories such as shelves, bins,

or attachments for securing specific types of loads. Adjustable features such

as handle height or shelf positions enhance usability and accommodate different

operator preferences or load requirements. Choosing a trolley with modular

components or interchangeable parts allows for easy maintenance and future

upgrades, extending its lifespan and functionality.

While upfront cost is an important consideration,

it's essential to evaluate the total cost of ownership over the trolley's

lifespan. Opting for high-quality trolleys may entail a higher initial

investment but can result in long-term cost savings through reduced

maintenance, repairs, and replacements. Consider factors such as warranty

coverage, maintenance requirements, and the availability of spare parts when

assessing the overall cost-effectiveness of a trolley. Additionally, factor in

the potential impact of downtime or accidents due to equipment failure, as

investing in reliable trolleys can help minimize such risks and associated

costs.

In conclusion, selecting the right heavy-duty trolley is essential for

optimizing efficiency, safety, and productivity in demanding industrial

environments. By considering factors such as load capacity, construction and

durability, maneuverability, safety features, and versatility, you can choose a

trolley that meets your specific requirements and withstands the rigors of

daily use. Investing in high-quality trolleys equipped with the necessary

features not only enhances operational efficiency but also contributes to a

safer and more productive work environment for your team.

Comments

Post a Comment