How Pallet Levellers Reduce Workplace Injuries?

Across various sectors, from warehouses to

manufacturing plants, the risk of workplace injuries looms large, often

exacerbated by factors like heavy lifting, repetitive tasks, and ergonomic

challenges. However, amidst these challenges, innovative solutions emerge to

mitigate risks and foster safer working environments. One such solution gaining

prominence is the utilization of pallet

leveller in Melbourne.

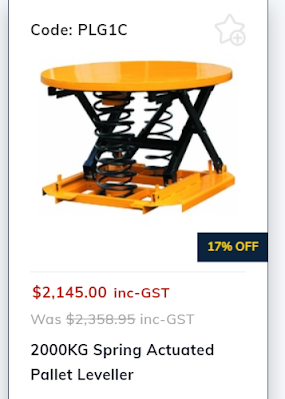

Pallet levellers, also known as pallet positioners or

pallet lift tables, are mechanical devices designed to adjust the height of

pallets to an ergonomic level. They offer a simple yet effective means to

eliminate the need for manual handling of heavy loads, thus significantly

reducing the risk of workplace injuries. Let's dive deeper into how pallet

leveller in Brisbane contribute to enhancing workplace safety.

Ergonomic Advantages

One of the primary benefits of pallet leveller in Perth lies

in their ability to promote ergonomic working conditions. Manual lifting and

lowering of heavy pallets can strain muscles and joints, leading to

musculoskeletal disorders (MSDs) such as back pain, strains, and sprains. By

automating the process of pallet positioning, these devices spare workers from

the physical exertion associated with such tasks.

Pallet

leveller in Sydney allow operators to adjust the height

of pallets with ease, ensuring that the load is always at the most suitable

level for loading and unloading. This minimizes the need for awkward bending,

reaching, or stretching motions that can put undue stress on the body.

Consequently, workers can perform their duties in a more comfortable and

ergonomic manner, reducing the risk of fatigue and injury over time.

Injury Prevention

Work-related injuries not only cause suffering to

employees but also result in productivity losses and increased healthcare

expenses for employers. Pallet leveller

in Adelaide play a pivotal role in injury prevention by

mitigating the hazards associated with manual material handling. By eliminating

the need for workers to lift or lower heavy pallets manually, these devices

significantly reduce the risk of strains, sprains, and other lifting-related

injuries.

Moreover, pallet levellers contribute to a safer

working environment by minimizing the likelihood of accidents such as slips,

trips, and falls. When pallets are positioned at an appropriate height, workers

can more easily access their contents without having to navigate around

obstructions or uneven surfaces. This reduces the risk of accidents caused by

uneven footing or collisions with nearby objects.

Increased Efficiency

In addition to enhancing safety, pallet levellers can

also improve operational efficiency within the workplace. By streamlining the

process of pallet positioning, these devices help to optimize workflow and

minimize downtime associated with manual handling tasks. Workers can load and

unload pallets more quickly and efficiently, allowing for smoother logistics

operations and faster turnaround times.

Furthermore, pallet levellers facilitate the

utilization of space within warehouses and storage facilities. By enabling

vertical stacking of pallets, these devices maximize storage capacity without

compromising accessibility. This is particularly advantageous in environments

where space is limited, allowing businesses to make the most of their available

resources without resorting to costly expansion projects.

Adaptability and Versatility

Another notable aspect of pallet levellers is their

adaptability to a wide range of applications and industries. Whether it's

manufacturing, distribution, retail, or logistics, these devices can be

customized to suit specific requirements and accommodate various types of

pallets and loads. From standard wooden pallets to specialized containers,

pallet levellers can handle diverse materials with ease, making them a

versatile solution for different operational needs.

Moreover, modern pallet levellers often come equipped

with advanced features such as automatic height adjustment, weight sensing

capabilities, and remote control options. These technological enhancements

further enhance usability and safety by allowing for precise control and

monitoring of the lifting process.

Conclusion

In conclusion, pallet

levellers represent a valuable investment for businesses seeking to

prioritize workplace safety and efficiency. By eliminating manual handling

hazards, preventing injuries, and enhancing operational productivity, these

devices offer a multifaceted solution to the challenges of modern industrial

environments. As employers continue to prioritize the well-being of their

workforce, the adoption of pallet levellers is poised to become increasingly

prevalent across various sectors, driving positive outcomes for both workers

and businesses alike.

Comments

Post a Comment